New Forged Hanger Components For The Clifton Suspension Bridge

The Clifton Suspension Bridge, a Grade 1 listed structure, is one of the oldest surviving iron suspension bridges in the UK. Spanning 214 metres across the Avon Gorge, the bridge has become one of Bristol’s top tourist attractions and an inspiration for bridge engineers all over the globe.

The bridge was designed by the world-famous engineer Isambard Kingdom Brunel who was awarded the project at the age of 24. Taking 33 years to complete, it marked the beginning of a great engineering career. When Brunel died in 1859, the bridge remained unfinished until his colleagues at the Institution of Civil Engineers raised the required funds to complete the bridge as a memorial to Brunel.

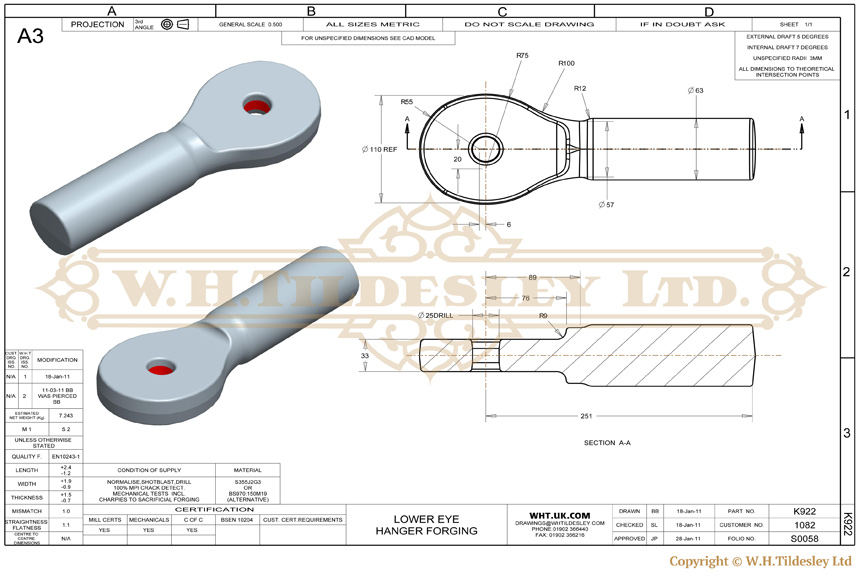

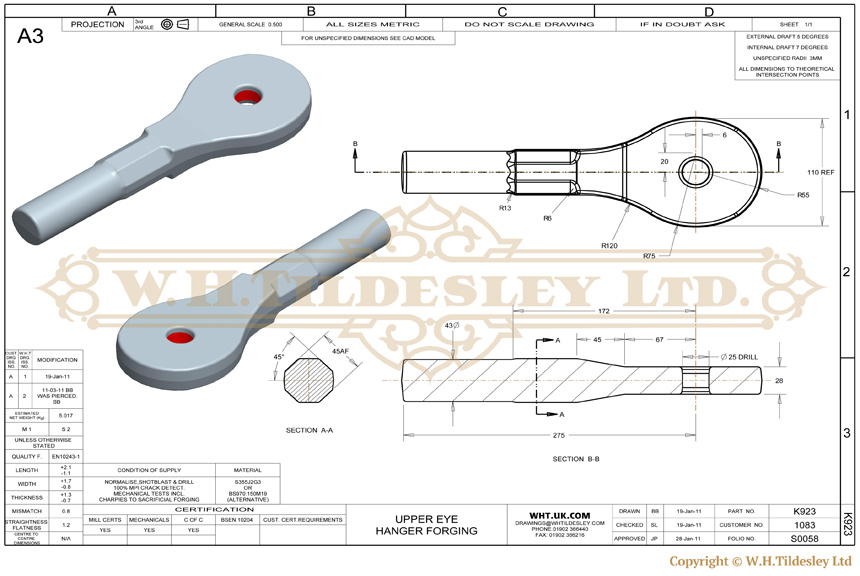

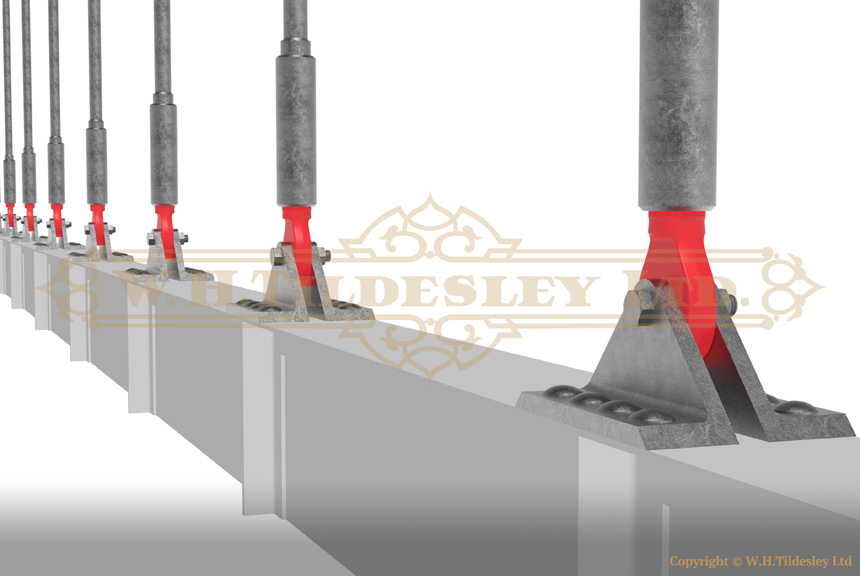

The maintenance and preservation of the bridge is a priority and is managed by the Clifton Suspension Bridge Trust. Key components of the bridge are inspected at regular intervals and replaced if showing signs of failure or fatigue. W.H.Tildesley was asked to reverse engineer the forged hanger ends and produce new components for the bridge. There are two styles of hanger ends, an upper and a lower design for each of the vertical hanger bars on the bridge.

The hanger eyes are produced using the latest drop forging techniques but remain faithful to the original techniques used in the 1800s. The new hangers are forged from S355J2 material and undergo 100% MPI crack detection. Full mechanical tests, including charpies, are performed on a sacrificial forging.

W.H.Tildesley is honoured to be part of the ongoing preservation of the Clifton Suspension Bridge and would welcome the opportunity to support similar projects worldwide.