History

W.H.Tildesley has its roots in Black Country industry and has been operating in Willenhall for over 150 years.

Throughout its long history, the WHT philosophy of attention to detail, customer service, and top-quality products has been a steadfast theme.

Supplying quality British drop forgings since 1874.

Founded by William Henry Tildesley in 1874, like most companies in Willenhall, W.H. Tildesley made parts for horses that were heavily used in the transport industry.

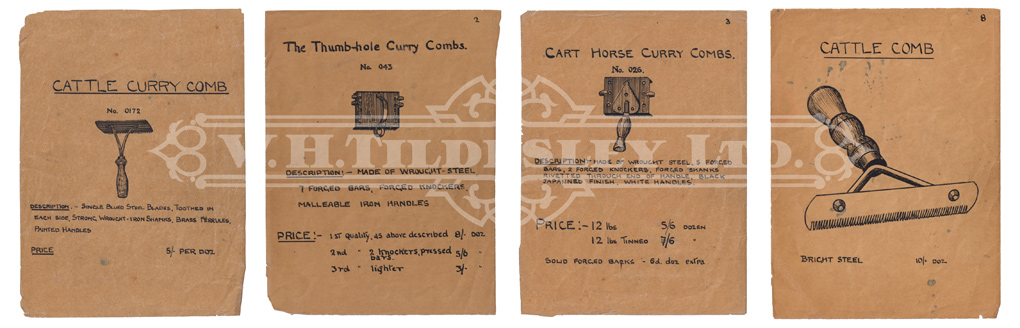

The production of horseshoe blanks started in 1880 in support of the Boer War. Other parts included horse grooming equipment – curry combs tail comb, sweat scrapers, then expanding into vermin traps. In those days Willenhall, in the West Midlands, was famous for lock making and metal work for the nearby Saddlery trade in Walsall.

|

|

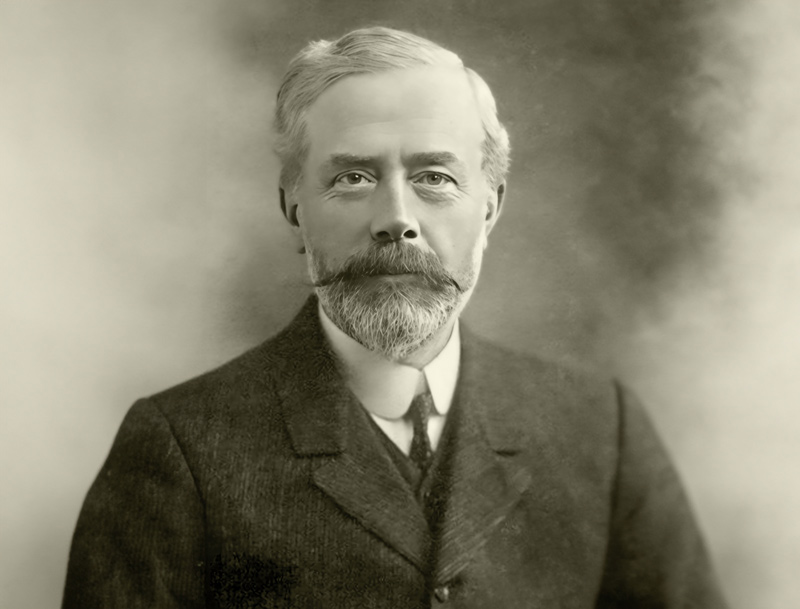

Founder - William Henry Tildesley |

During the 1st World War, production switched to mass manufacturing of horseshoe blanks. It was as a result of this that the little family business moved down the road to its present site to carry out the noisy and hot blacksmith-type work. But diversity and adaptation have always been part of the culture and the product range soon expanded to include drop forgings. Horace William Tildesley, the son of William Henry Tildesley, took the business further and the forging operations became the heart of the WHT business.

|

|

W.H.Tildesley's Horse Grooming Equipment – Curry Combs, Tail Combs, and Sweat Scrapers |

Horace’s son David Henry Tildesley fought in the Second World War earning two Military Crosses for his bravery and courage. He succeeded his Father after the Second World War building the business to be financially secure and investing in new equipment.

David Henry Tildesley was succeeded by his eldest son Richard as Managing Director in the early 80s and WHT became a major forging supplier within the UK and export market. Richard's younger Brother John Tildesley joined the business in the late 80s and as Technical Director began a programme of investment forging technology that continues to this day. Between them, they developed applications in a wide range of markets such as admiralty lifting and rigging equipment, motorcycles and trucks, and architectural ironwork.

|

|

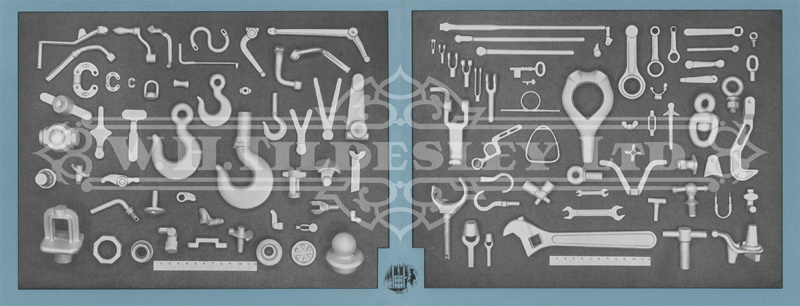

Old Literature Extract - Collage Of Typical Drop Forged Components |

Sadly Richard died prematurely and John took on the mantle as Managing Director and brought the business very much into the 21st century. Family connections have also played a part in workforce development with many of WHT's current staff being related to current and previous employees.

Whilst the high-volume production of many of our traditional parts has moved overseas, WHT still maintains a niche position in those markets especially where small and medium quantities of unique parts are required, often on short lead times for repair and maintenance. The ability to produce small batches cost-effectively is now central to our current market position and continuous investment in capital equipment, materials technology, training, and information technology means that we also now offer a vital service to today's key industries such as railways, oil/gas, petrochemical, and off-road equipment.

In a world where outsourcing has become increasingly fashionable, WHT continues to invest in its capabilities, particularly in-house die-making and finished component machining. WHT's evolution has seen a massive advance in production techniques and the streamlining of material procurement which has been crucial to maintaining competitiveness. Continually investing in our plant, processes, and people, we embrace the most modern industry and have the advantage of historical evolution behind us.

Our extensive historical drawing archive features drop-forged components produced from the early 1900s

Our heritage is thoroughly documented in our drawing archives, spanning over 100 years of drop forging production at the site in Willenhall, West Midlands. All drawings are professionally bound and archived until this day, the oldest being from 1908 when the archive was implemented.

For preservation, all drawings have recently been professionally digitally collated and scanned, all of which are now available to preview on this dedicated website by using the search function at the top of this page or by visiting any of our heritage customer brand pages.

We have also collated and archived our original handwritten job production cards that tell us who was making what component and when, how many they produced, the rate of pay, etc.

Digital drawings and 3D models for all jobs dating from 2000 to the present day

Even though all drawings are still printed, bound, and archived to this day, WHT implements the latest in digital drawing and 3D modeling software. We have digital models and drawings that cover the last 25 years of drop-forging production. 3D Models from this archive can be die-cut overnight and entered into the production schedule in a matter of days.

W.H. Tildesley was the OEM for many British Companies including

|

|