3D Printing

A process that enables the production of dimensionally accurate models, typically in PLA or ABS plastic material.

Once the forging shape for the final component is digitally modelled using the latest 3D design software we have the capability to 3D print a physical sample.

This can be just the final raw forging or a model with any final machining requirements. With this technique, the customer can determine the suitability of the final forged parts, and approve or make any minor adjustments before any investment in production tooling is made.

We prefer to 3D print our models in two halves, mirroring the split die line on the final set of forging tools.

With this in mind, the same technical feasibility rules apply to 3D printing and closed die drop forging.

|

|

|

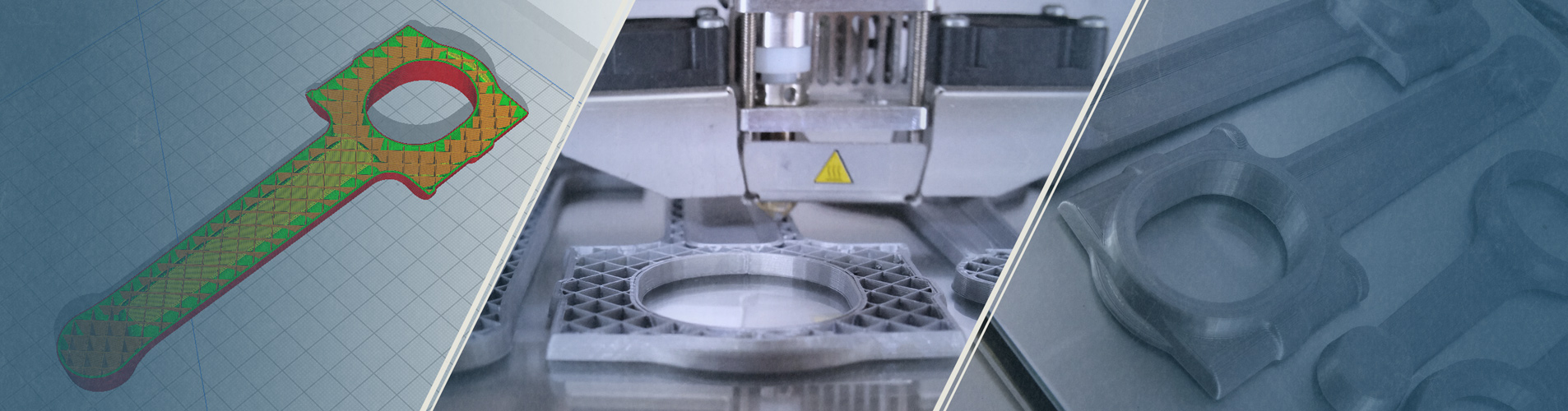

Modelled |

Sliced |

Printed |

Steps for 3D Printing a Sample

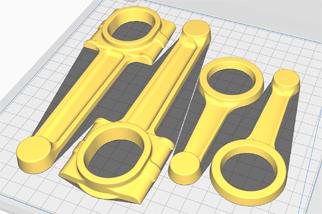

1. A 3D model of your heritage component is created as a standard if moving forward with us.

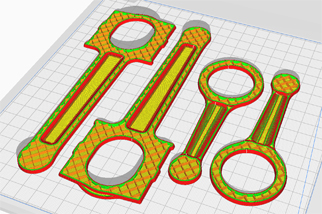

2. The 3D model is imported into 'slicing' software. A 3D print is made up of layers and these are called 'slices'. Parameters can be set at this stage to determine if a part is solid or honeycomb, etc.

3. GCode is exported from the 'slicer' software to the 3D printer and the printing process can commence.

4. As we prefer to print parts in halves to mirror the forging die split line, the finished prints are bonded together to form the final model for customer review.