Drop Forging

Drop forged heritage components from 25 grams up to 75kg net weight, produced in the UK's most modern forge.

We are the closed die drop forging experts and one of the leading drop-forged component producers in the UK.

Our recent plant upgrade and expansion means we have the most modern metal drop forging facility in the UK. We currently have a total of nine power and drop hammers with a power rating ranging from 350Kg to 5 Tonne.

We have the ability to forge a wide range of ferrous and non-ferrous materials ranging from standard carbon & alloy steels, duplex, super duplex, nickel superalloys, and other non-ferrous alloys.

Our drop forging process is fully supported by our other services. Component design, forging feasibility and optimisation through CAD modeling and simulation, in-house tool room for quick turnaround of dies, in-house machine shop for proof or finished machined components.

|

|

Drop Forged Components

W.H.Tildesley can manufacture a wide range of drop-forged components for many demanding industries worldwide.

Some examples of these components are shown below.

|

|

|

Connecting Rods |

Top Links |

Stub Axles |

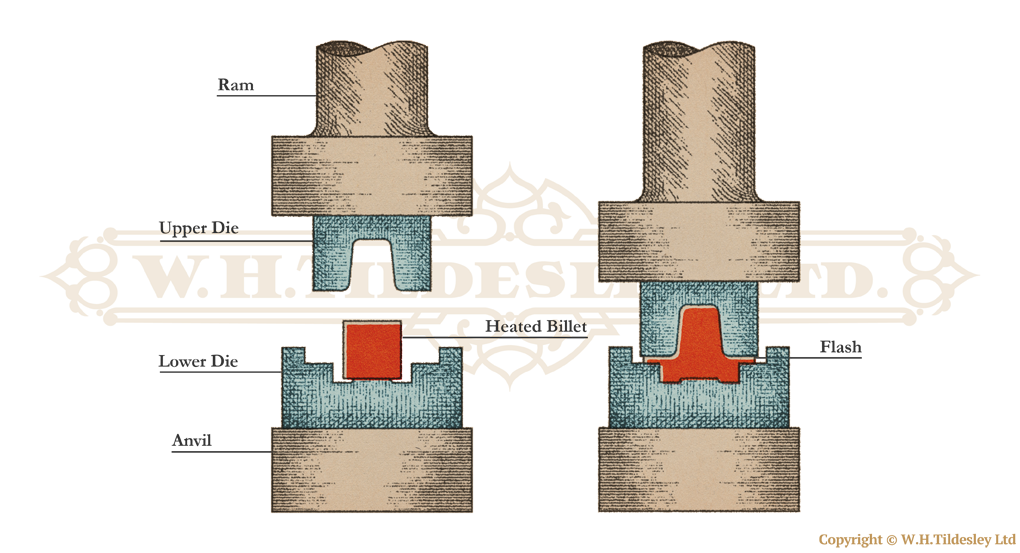

The Closed Die Drop Forging Process

In the closed die drop forging process, a metal bar or billet is heated before being placed in the die and then hammered until the metal completely fills the die cavity. The process can also be called impression die forging.

During this process of plastic deformation, the material’s grain structure becomes compressed and aligned to the component shape which imparts greatly increased directional strength with reduced stress concentrations in corners and fillets. Components manufactured this way are stronger than their equivalent machined-from-solid or cast parts.

Latest Certifications & Approvals

W.H.Tildesley is committed to ensuring that the products and services we provide consistently meet the needs and expectations of our customers.

Drop Forgings Provide Improved Strength to Weight Ratio

In the closed die drop forging process, a metal bar or billet is heated before being placed in the die and then hammered until the metal completely fills the die cavity. During this process of plastic deformation, the material’s grain structure becomes compressed and aligned to the component shape which imparts greatly increased directional strength with reduced stress concentrations in corners and fillets. Components manufactured this way are stronger than their equivalent machined-from-solid or cast parts.

Structural Integrity

Drop forging a component greatly reduces the possibility of metallurgical defects such as porosity or alloy segregation as found in some castings. This leads to reduced scrap, a uniform response to heat treatment, and predictable component performance in the field.

There is virtually no possibility of porosity being introduced during the drop forging process. Even this can be checked with a low-cost ultrasonic test after manufacture. The possibility of small surface cracks can be managed with a simple crack detection procedure towards the end of the process.

Post Forging Machining

Parts can be machined post-forging with no loss of quality because there are no voids or porosity in the fished article. Forging is often combined with machining for improved dimensional accuracy. This can also be achieved by post-forge coining or sizing.

Cost Benefits

Moving from machined-from-solid to forged components generates a saving in raw material usage. Starting from a near-net-shape forging can also reduce machining times. This means companies moving from machine-from-solid to machine-from-forging can generate enough capacity on their existing plant to save capital outlay on new machinery, as their business grows.

Customers often assume that the initial tool cost required for near-net shape forging is prohibitive. Forging dies and tools are quite simple in construction and are relatively low-cost, making them viable even for jobs with low production quantities. This cost can be further mitigated by amortisation into the component piece price and even reclaiming pre-used die materials.

Die Life

Closed die drop forging tools typically last between 5000 and 7000 cycles in more common carbon materials but can be as low as 100 cycles where very complex shapes are required in high-strength super-alloys. Die life expectancies are greatly reduced by sharp corners, material forge-ability, and very close tolerances. Some of these limitations can be offset by incorporating multiple impressions into the die design or by pre-forming the metal billet before putting it into the dies.

Cycle Times

Forging cycle times are rapid: a typical forging is often complete within 10-30 seconds. However, some complex shapes require complex procedures where the level of skill and experience of the Stamper plays a key part.

Design Opportunities

This process is suitable for low-volume production as well as one-offs. This is because it produces parts with superior strength-to-weight properties that cannot be manufactured in any other way. Small volumes can be machined from solid, but they will have to compensate for reduced strength brought about by random grain alignment.

Undercuts are not possible in forging, however, it is possible to form undercuts and form joints with secondary forging operations. These processes can be used to make a huge range of component sizes and geometries.

Design Considerations

Designing for forging must take into account several factors including partition line, draft angles, ribs, radii, and fillets. Parts are formed by hammering, or pressing, which can produce surprisingly deep protrusions, up to 6 times the thickness of the material. Draft angles can be minimised and even eliminated by clever design, especially in ductile materials like aluminium (aluminum) and brass. Radii, however, are very important because they encourage the flow of metal and reduce tool wear. The minimum radius increases with the depth of protrusion.

Compatible Materials

Most ferrous metals can be forged, including carbon, alloy, superalloy, and stainless steel. Non-ferrous metals including aluminium (aluminum), brass, copper, and titanium are also suitable.

Environmental Impacts

A Forge is a relatively dangerous process to work and health and safety are maintained by operator training, controlled production procedures, and involvement of the workforce.

Noise and vibration can be managed with up-to-date damping under the hammer unit and the correct building structure.

The forging process provides optimum use of materials with little waste. All trimmed flash and offcuts are recycled and of course, all-metal components can be recycled at the end of their life-cycle.