Replication Guide and Considerations

So, you have a part requiring replication. Fantastic. However, there are a few things to consider before reaching out to us.

Please read the below guide and considerations to be taken into account for heritage part replication.

The forging process (not to be confused with casting) will require investment in tooling and dies. Without tooling no forging can be produced. Please see a rough estimate of tooling costs further down this page.

The quantity of parts required also plays a key factor in the final cost. The setup, overhead, and production costs are the same for 1 part as they are for 200 parts with the only variable being how many are made per hour.

At W.H.Tildesley we are happy to accommodate low-volume production but the costs are greater as the absorption of our production costs is restricted. With this in mind, at the quotation stage, we are happy to provide you with price breaks based on various batch sizes.

The Replication Process

Firstly, an introductory meeting is arranged so we can view any samples and drawings you have available. We will also discuss your project in more detail to establish your expectations and requirements.

|

|

A meeting is typically required so we can look at your component samples and discuss your requirements |

If we are confident that we can proceed, a further feasibility study is undertaken. We must consider the shape, size, material, finishing, and quantity required as this impacts tooling, production rates, and final component costs.

Tooling Costs

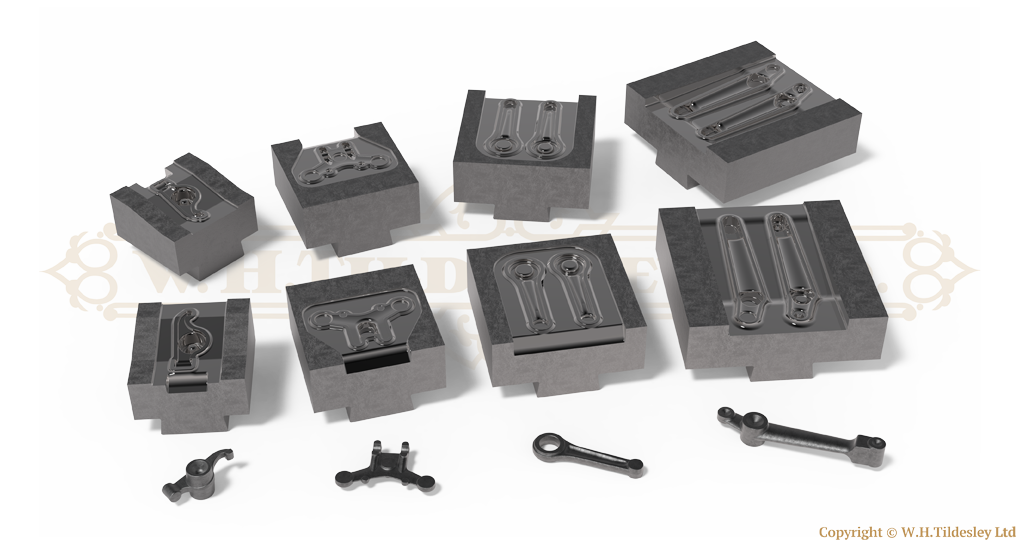

The biggest cost for any new forged component project is the tooling which is charged separately as a one-off cost. This typically consists of a set of forging dies that includes a molder and finisher and a clipping tool that removes excess material. In most scenarios, the forge retains ownership of the actual die block, and the customer exclusively owns the impression of the component that is cut into it. The forge is fully responsible for maintaining and replacing the dies for the duration that the component is in production with us.

A few factors including size and complexity influence the cost of a tooling set. As a guide, the following should be an expected cost to proceed with forging.

Forge Tooling Cost Estimate Scale

Small Component - £1,500 - £3,000

Medium Component - £3,000 - £5,000

Large Component* - £5,000 - £10,000

*Maximum size 600mm² and weight of 75kg nett.

At this stage, we would be in a position to offer you an official quotation for your components and the exact cost of the tooling required. Once your official order is received we can move forward and invest further time in reverse engineering processes as detailed below, ultimately leading to final production.

Reverse Engineering

In typical cases of heritage replication, the original manufacturer drawings are no longer available and a reverse engineering process is required to generate a new 3D model and accompanying technical production drawings. Various traditional techniques can be applied such as physical observation and dimension taking of an original sample but we have the added advantage of more modern 3D scanning and 3D printing to verify data before production.

3D Scanning

This is a method used to scan original components and generate a digital 3D mesh model. This is used to compare the original part to the newly generated digital model that is prepared by our skilled technical design engineers. Any deviation from the original sample is easily identified and can be rectified before proceeding to the next stage of production.

3D Printing

Once the forging shape for the final component is modelled using the latest 3D design software we have the capability to 3D print a physical sample. This can either be of the final raw forging or a model that includes any final machining requirements. With this technique, the customer can determine the suitability of the final parts, and approve or make any minor adjustments before any investment in production tooling is made.

Metallurgical Analysis

As with most components produced decades ago, it is difficult to establish what material it was produced from without the aid of original production drawings. We have in-house metallography capability which allows us to examine grain flow and microstructures of raw material and forged components. Through the use of non-destructive positive material identification (PMI) testing, we can determine the original chemical composition of the original components. Combining this data with our production knowledge of modern equivalents enables us to recommend a suitable material for reproduction. At this stage, it is also possible to consider alternative metals that can improve durability or aid in weight reduction. Once decided, raw material costs can be obtained and applied.

Forging Simulation

Our team has a disciplined approach to forging and tooling design and access to the latest forging simulation software available. This enables us to evaluate the overall forging process before any major cost is incurred and select the optimal forging machine for production. The software is programmed with an extensive library of data that is unique to our forging machines and production methods. This allows us to look at the suitability of raw material, tooling design affecting overall wear or under-fill in the impression, and the flow and compression of grain within the component.

Die & Tooling Manufacture

The production of forging dies and other tools, jigs, and fixtures are kept in-house, utilising our longstanding toolroom staff who have decades of combined knowledge of our processes and production equipment. All forging dies are machined using high-speed machining centers with the latest cutting technology.

Drop Forging

Once forging dies are complete, the final stages of component production can proceed. Our extensive drop-forging capability is still on the original site established in 1874. The technicalities of the process have not changed but with advancements in modern engineering the overall efficiency is improved and larger power hammers are available at our facility.