Forging Simulation

Simulation software ensures we get it right the first time, every time.

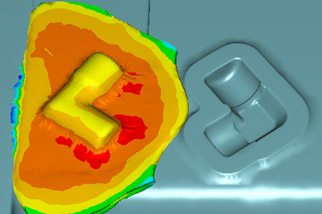

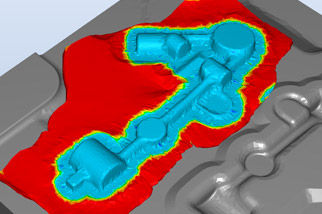

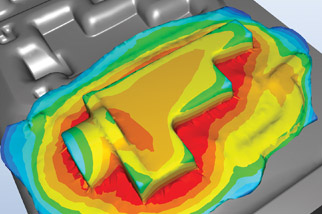

Our team has a disciplined approach to forging and tooling design and access to the latest forging simulation software available. This enables us to evaluate the overall forging process before any major cost is incurred.

The software is programmed with an extensive library of data that is unique to our forging machines and production methods. This allows us to look at the suitability of raw material, tooling design affecting overall wear or under-fill in the impression, and the flow and compression of grain within the component.

Software Solutions

W.H.Tildesley uses the latest in forging simulation software, Quantor Form and Transvalor. This is combined with the latest industry-standard CAD and CAM software. This includes 3 seats of CREO and Solidworks.

|

|

|