Die Manufacture

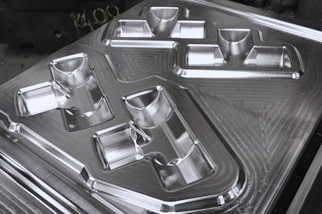

Forging dies and tooling for heritage projects are produced in-house, guaranteeing quality and improved lead times.

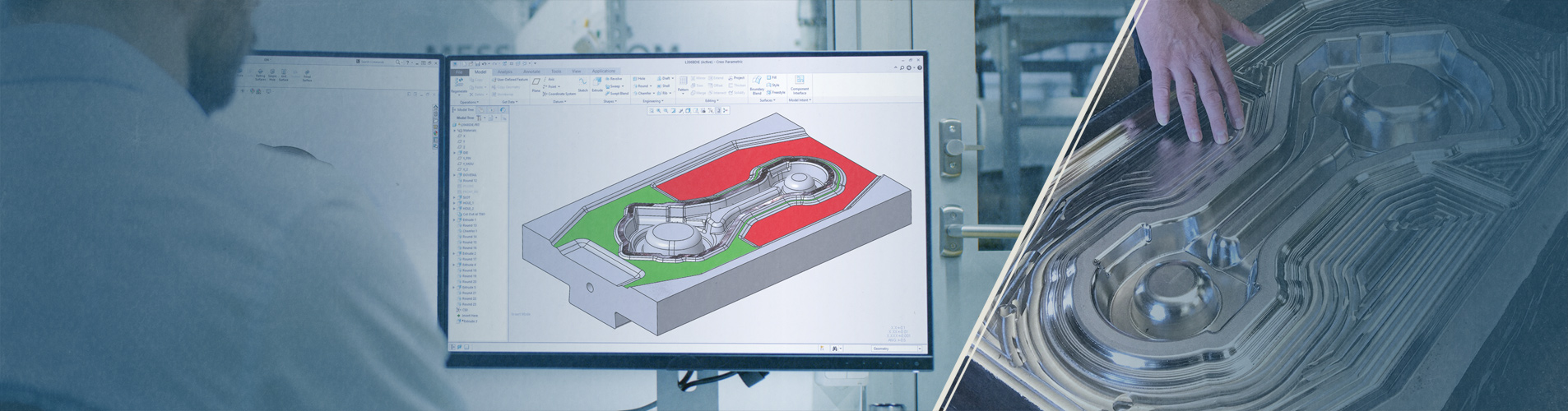

Our fully integrated CAD/CAM package links product and die design to high-speed die sinking using two Matsuura machining centers with the latest Hitachi cutting tool technology.

By keeping this process in-house, we can utilize the expertise of our technical staff who are familiar with our processes and equipment. This guarantees that we produce the correct tooling for our hammers and the end component is manufactured in the most efficient and economical way possible.

|

|

|

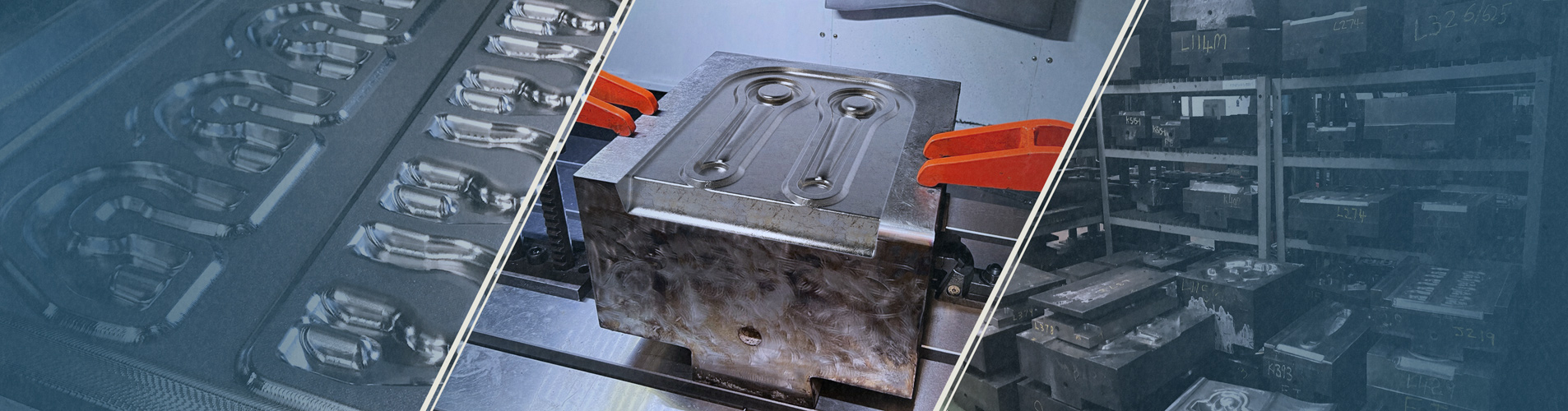

CNC Machining |

Fettling |

Final Die Tool |

All die blocks are machined in the hardened state. This not only saves time but eliminates the risk of distortion during heat treatment.

In addition to the rapid production of dies for new product designs, those required for regular production can be re-sunk overnight to ensure their readiness at all times.