About Us

The W.H.Tildesley Heritage Division specialises in the replication & production of forged components for historical vehicles & projects.

W.H.Tildesley Ltd, established in 1874, is one of the oldest drop forging companies remaining in the United Kingdom.

A recent £1.4 Million refurbishment means that we now have the most modern drop forging facility in the UK. Our extensive in-house capabilities enable us to offer an efficient service by reducing the use of sub-contractors and improving quality and lead times.

|

|

Drop Forging

Drop forged components from 25grm up to 75kg net weight. Die size up to 600mm²

We have the ability to forge in a wide range of ferrous and non-ferrous materials ranging from standard carbon & alloy steels to stainless, duplex, nonferrous, and superalloys.

Machining

Extensive in-house machining capability for proof or finish machined forgings and tooling production

We can carry out a full range of complex or simple machining operations on forgings that are drop forged at our factory or supplied to us on a free-issue basis.

Component Design

We provide full engineering support at the product design stage of the forging process

Our skilled team of engineers and experienced technicians are here to assist us and our customers, ensuring that components are fully optimised for the drop forging process.

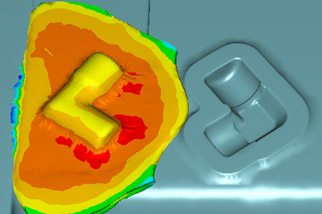

Forging Simulation

Simulation software ensures we get it right the first time, every time.

The use of forging simulation software enables us to evaluate the overall process before any major cost is incurred.

Die Manufacture

All of our tooling and forging dies are produced in-house, guaranteeing quality and improved lead times

Our fully integrated CAD/CAM package links product and die design to high-speed die sinking using two Matsuura machining centres with the latest Hitachi cutting tool technology.

Quality Control

Quality processes and certifications to meet the thorough demands set by the industries we supply

At W.H.Tildesley we believe that quality is king and are recognised as a leading drop-forged component supplier in many markets and industries worldwide.

Surface Finishing

We can offer several surface finish options to suit customer requirements

Many of the forged components produced at W.H.Tildesley often go through additional surface finishing, as per customer requirements. Our forgings are always supplied in the shot blast condition.

Heat Treatment

Heat-treated forged components for the toughest applications

W.H.Tildesley works in partnership with leading heat treatment companies to meet international standards and customer material specifications for the finished condition of all grades of material.

Certifications & Approvals

W.H.Tildesley is committed to ensuring that the products and services we provide consistently meet the needs and expectations of our customers.