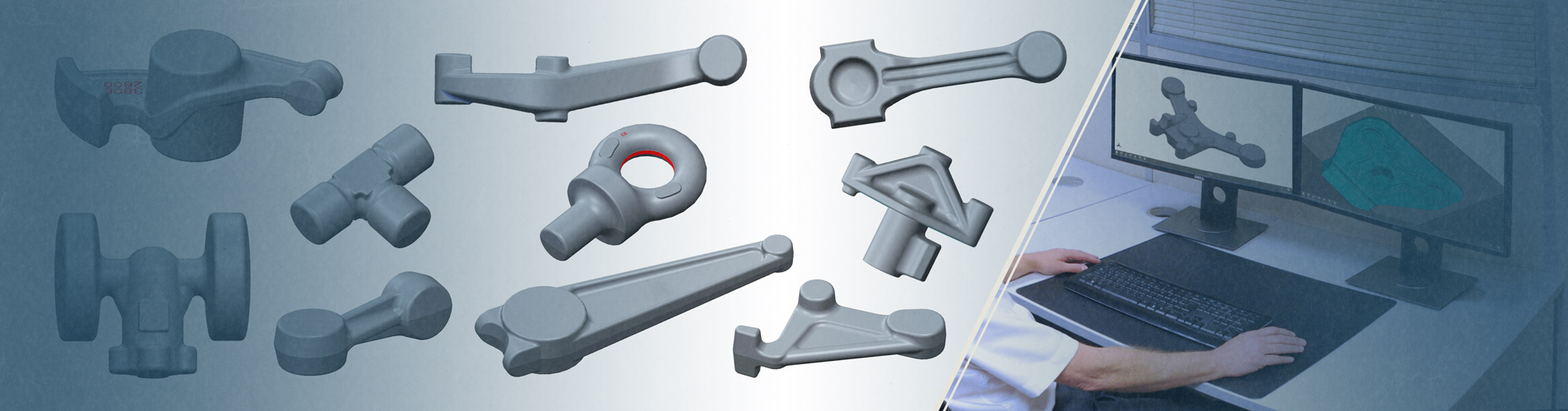

3D Design

We provide full engineering support at the component design stage of the forging process.

Our skilled team of engineers and experienced technicians are here to assist you, ensuring that components are fully optimised for the drop forging process.

Reverse Engineering

Reverse engineering plays a vital part in the production of new forged heritage components that are often required due to depleted new old stock or are no longer available in the marketplace. We can work with our customers and create new tooling, component drawings, and digital 3D models from original physical samples. Freshly created model files can be put through a forging simulation program, fully optimising the forging process before any costly tooling or materials are produced.

Forging Simulation

Forging simulation is a cost-effective way to evaluate the overall process before any major cost is incurred. Every component that is produced at W.H.Tildesley is 3D modeled and run through simulation software to develop part geometry and test tooling design. This helps identify forging defects such as cracking or under-fill.

Software Solutions

We are currently using the latest industry-standard in CAD and CAM software. This includes 3 seats of CREO and Solidworks. We can work with DXF, DWG and PDF format, and 3D model files in STEP or IGS.

3D Printing

When required we can take our digital 3D models and produce them in a physical format using 3D printing. Typically in PLA or ABS plastic, these models are accurate to within 0.2mm and are ideal for test fitting in final applications.